Ansi Asq Z1 9 2008 Pdf Editor

ASQ Z1.4-2008 and Z1.9-2008 SET ASQ Z1.4-2008 and Z1.9-2008 SET Sampling Procedures and Tables for Inspection by Attributes (Z1.4-2008) and Sampling Procedures and Tables for Inspection by Variables for Percent Nonconforming (Z1.9-2008) SET American Society for Quality / 2008 / 213 pages. ANSI/ASQ Z1.13-1999. Convert Pdf To Txt Files In Ansi Code Codes and Scripts Downloads Free. Aostsoft PDF to Office Document Converter is a competent and utility program specially used to batch convert PDF to Word(. How to Manipulate Files in ASP.

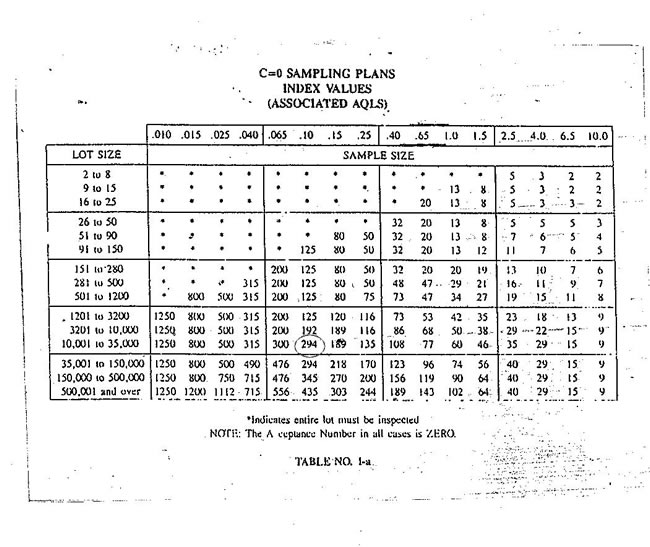

This standard is a revision of ANSI/ASQC Z,. “Sampling Procedures and Tables for Inspection by. Attributes.” Beyond editorial refinements, only the. Know the switching rules for ANSI/ASQ Z Categorize the various sampling plan systems in terms of lot-by-lot, continuous production, attributes or variables. ANSI/ASQ Z Sampling Procedures and Tables for Inspection By. Attributes The FDA recognizes ANSI/ASQ Z as a General consensus standard.

Ansi Asq Z1.4 Table Free

| Author: | Zuzuru Vulrajas |

| Country: | Congo |

| Language: | English (Spanish) |

| Genre: | Science |

| Published (Last): | 4 July 2011 |

| Pages: | 469 |

| PDF File Size: | 20.23 Mb |

| ePub File Size: | 2.44 Mb |

| ISBN: | 486-9-21793-340-5 |

| Downloads: | 48279 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Mazubei |

On the other hand, if the lot sampling is to detect lots with specific faults, isolated to a specific specification then the defect types would be considered separately. I wish there was a simple answer. These rules are designed to encourage suppliers to have process averages consistently better than the AQL. If the inspection ansii requires lot sampling, then all of the basic lot sampling guidelines apply. Acceptance Sampling With Rectification When Inspection Errors Are Present, Journal of Quality Technology In this paper the authors consider the problem anwi estimating the number of nonconformances azqc in outgoing lots after acceptance sampling with rectification when inspection errors can occur.

They show the average sample size for scheme performance when using single sampling. Use corresponding double sampling plan.

The standard 1z.4-2008 not intended as a procedure for estimating lot quality or for segregating lots. Table X-D—Tables for sample size code letter: It is expected that the product quality level will be less than the AQL to avoid excessive non-accepted lots. If the document is revised or amended, you will be notified by email.

Normal inspection will be used at the start of inspection unless otherwise directed by the responsible authority.

ASQC Q contains sampling plans that have been calculated on this basis and therefore provide a more accurate set of tables for these situations. We want to ensure that we are receiving clean containers to package our products.

AOQL values are given in Table V-A for each of the single sampling plans for normal inspection and in Table V-B for each of the single sampling plans for tightened inspections. The number of nonconformities per hundred units of any given quantity of units of product is one hundred times the number of nonconformities contained therein one or more nonconformities being possible in any unit of product divided by the total number of units of product, i.

Is this instance, more than ten lots or batches may be used for the calculation, provided that the lots or batches used are the most recent ones in sequence, that they have all been on normal inspection, and that none has been rejected while on original inspection. Components and raw materials.

The number of sample units inspected shall be equal to the sample size given by the plan. If sample size equals or exceeds lot or batch size, do percent inspection. However, Inspection Level I may be speci?

Subscription pricing is determined by: The sample size to be used is given by the new code letter, not by the original letter. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute. Three types of sampling plans: As necessary, the supplier shall provide adequate and suitable storage space for each lot or batch, equipment needed for proper identi?

This standard is intended to be used as a system employing tightened, normal, and reduced inspection on a continuing series of lots to achieve consumer protection while assuring the producer that acceptance will occur most of the time if quality is better than the AQL. If you use one of the special sampling plans based on the cost of the test, it is helpful to calculate the actual AQL and Limiting Quality LQ using the following formulas.

Once that confidence is restored, then you go back to what you inspected originally. Ideally, a very fast, effective and non-destructive inspection method is preferred over a slow, error prone, and destructive approach.

Z1.4:2008 inspection levels

When no sampling plan is available asqqc a given combination of Z1.4-200 and code letter, the tables direct the user to a different letter. Skip to content Z1.4-208 Original inspection is the? American National Standards are subject to periodic review and users are cautioned to obtain the latest editions. My concern with the current method is that you may have a lot of extra paperwork to account for everyone for a certain time.

My second question is if I have a batch that passes acceptance sampling but at a subsequent downstream process a defect being inspected for by the upstream acceptance sampling inspection is found how do I determine if the lot is acceptable?

Zero defect sampling is an alternative method to the obsolete Mil Std E sampling scheme previously used to accept or reject products, and the remaining ANSI Z1.

Ssqc the use of this standard it is helpful to distinguish between: When agreed upon by responsible authority for both parties to the inspection, that is, the supplier and the end item customer, the requirements of 8. Once on tightened inspection, unless corrective action is taken to improve product quality, it is very likely that the rule requiring discontinuance of sampling inspection will be invoked.

ANSI/ASQ Z1.4–2003 (R2013): Sampling Procedures and Tables for Inspection by Attributes

Ansi Asq Z1 4 2013 Pdf

The term scheme performance is used here in a very restrictive sense. Less discrimination means that z14-2008 actual Acceptable Quality Level AQL on the table underestimates the true AQL, as the sample size has been reduced from the table-suggested sample size i.

The operating characteristics and other measures of a plan so chosen must be assessed individually for that plan from the tables provided. The responsible authority shall determine whether normal or tightened inspection shall be used on reinspection and whether reinspection shall include all types or classes of nonconformities or only snsi particular types or classes of nonconformities which caused initial rejection.

Z inspection levels –

Ansi Asq Z1 4 2008

Please first log in with a verified email before subscribing to alerts. To me, it feels like the first step should be to determine the AQL. Need more than one copy?

The ideal method of calculating the sample size and risk is by use of the hypergeometric probability function.

AOQL will be slightly higher when the limit numbers for reduced inspection are not used under Option 8. When several types of plans are available for a given AQL and code letter, any one may be used.